What Is AOI (Automated Optical Inspection)?

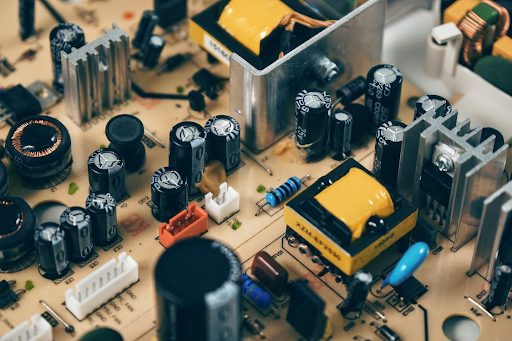

Automated Optical Inspection, commonly known as AOI, is a machine-based inspection technology that enables the detection of defects and flaws in various production processes, including PCB and electronics manufacturing, automotive, medical, and aerospace industries.

AOI machines, on the other hand, use advanced computer vision algorithms and diverse lighting techniques to detect and classify inconsistencies in manufactured products accurately. AOI in PCB Manufacturing is used for the visual inspection of completed circuit boards, to detect component alignment, missing components, mislabeled components, and other defects.

Automated optical inspection systems have dramatically transformed the landscape of PCB inspection and are widely used for quality assurance purposes in modern manufacturing facilities. It involves a machine scanner, multiple light sources, and cameras, to scan and inspect circuit boards using light imaging.

V1A045 TM Robot – Case Study – Continental Automotive Hungary

What Does Automated Optical Inspection Do?

AOI machines utilize a variety of features but we have here 10 benefits of using AOI technology in the PCB manufacturing process:

- Increased Accuracy: AOI in PCB utilizes high-resolution cameras and advanced algorithms that can detect even the smallest defects or deviations from design specifications. It can perform measurements with micrometer precision, ensuring that all components and finished products meet the required quality standards.

- Cost Savings: AOI can help manufacturers reduce production costs by detecting defects early in the manufacturing process, thus preventing the production of faulty products. This helps avoid unnecessary expenses such as material waste, product recalls, or customer complaints.

- Improved Productivity: AOI machines can operate at high speeds and are capable of inspecting thousands of units per hour, making it ideal for high-volume production environments. This helps manufacturers increase their efficiency and output while maintaining the desired quality standards.

- Enhanced Quality: With AOI in PCB, manufacturers can verify the quality of their products before they are released to the market. This helps ensure that the products meet their intended performance and reliability specifications and helps maintain the brand’s reputation for high-quality products.

- Increased Reliability: AOI machines are equipped with technology that can identify even the most subtle defects, such as hairline cracks or micro-soldering issues, which can compromise the reliability of electronic products. It can also verify the integrity of the components and circuitry, thereby reducing the risk of product failures.

- Faster Time-to-Market: AOI technology can help manufacturers accelerate their product development process by detecting and correcting defects during the production phase, enabling them to release their products to the market faster.

- Greater Customer Satisfaction: Automated optical inspection aid manufacturers ensure that their products meet or exceed their customers’ expectations for quality, reliability, and performance. This enhances customer loyalty and satisfaction, thus strengthening the brand’s reputation in the market.

- Compliance with Regulations: AOI can help manufacturers comply with regulatory standards which require manufacturers to ensure that their products are free from hazardous materials and meet specific quality standards.

- Reduced Downtime: AOI can help reduce downtime caused by manual inspection processes or equipment failures by detecting defects early and alerting operators to address issues before they escalate.

- Improved Safety: AOI can help ensure that products are safe to use, by detecting defects such as loose connections, soldering defects, or inadequate insulation that can lead to electric shock or fire hazards.

In essence, automated optical inspection systems offer numerous advantages to manufacturers, from improved productivity and cost savings to enhanced reliability and customer satisfaction. As technology continues to advance, AOI systems are becoming more sophisticated and capable of detecting even the most subtle defects. This makes AOI technology an invaluable tool for manufacturers looking to improve their efficiency and quality assurance processes.

Benefits of Introducing AOI into PCB Production

The introduction of AOI technology in the PCB production process has revolutionized the industry. AOI machines offer a number of advantages over traditional manual inspection methods, such as improved accuracy, enhanced reliability, faster time-to-market, and cost savings.

The conception and application of AOI in PCB have made the production process faster, more reliable, and more efficient. And this has translated to cost savings for manufacturers and increased satisfaction for their clients. There is no doubt that AOI technology is the way to go for the PCB production industry. Here are some more benefits of introducing AOI into PCB production:

Higher Production Efficiency

The introduction of AOI into the PCB production process has led to higher production efficiency. AOI technology improves production efficiency by reducing the time needed to conduct quality control checks, thereby making it possible to produce PCBs on a 24/7 basis.

This translates to increased production output, faster turnaround times, and lower production costs. The machines are designed to operate without rest and can perform an endless number of inspections with the same level of accuracy.

Increased Inspection Quality

Manual inspections are prone to error, and the degree of accuracy is limited by the human eye’s capabilities. AOI technology, on the other hand, offers unmatched accuracy. The machine is designed to inspect each PCB meticulously, ensuring that no defects are overlooked. The technology can inspect small details that would be impossible for human eyes to detect. Thanks to several optical sensors, AOI systems are able to detect even the smallest defects and inaccuracies in the PCBs.

Identification of Defect Patterns

One of the most significant benefits of introducing AOI technology in the PCB production process is its ability to identify defect patterns. The system uses sophisticated software algorithms to identify patterns in the defects. This information can be used to adjust faulty processes and ensure that the production line operates optimally.

By identifying defects early on in the assembly line, the production line can continuously improve, and product quality can be consistently maintained.

V2A018 TM Robot – Automated Robotic Optical Inspection (AOI)

Smart Software for a Comprehensive AOI System

Introducing the cutting-edge software solution that will revolutionize your factory’s AOI operations: TM AI+ AOI Edge. Designed to address the challenge of integrating multiple cameras from disparate workstations into a centralized control system, our smart vision software harnesses industry-leading technologies to streamline and enhance your factory’s automated optical inspection systems.

At the core of TM AI+ AOI Edge is a powerful IPC that can be easily installed on your workstations. By connecting multiple cameras to the IPC, users can seamlessly operate our TMvision functions to execute a wide range of vision tasks, including object identification, image enhancement, measurement, and more.

With TM AI+ AOI Edge, your factory’s AOI operations will benefit from a host of advanced features, including intelligent defect classification, adaptive inspection algorithms, and unparalleled scalability that can be easily integrated with your existing production line.

Additionally, when paired with TM AI+ Training Server’s advanced analytics and data visualization tools provide real-time insights into your production line, allowing for faster, more effective decision-making. Our sophisticated AI algorithms and machine learning capabilities empower users to quickly and accurately identify defects, reducing downtime and improving overall production efficiency.

Automate with Us!

Techman Robot’s AI cobots offer a comprehensive solution for automating your factory’s AOI applications and increasing production efficiency. Whether it’s material handling, AOI inspection, or palletizing, these tools provide ease of use and versatility, making them ideal for a wide range of applications.

With our software solution, you can rest assured that your AOI applications are in good hands. Our team of experts is dedicated to providing the highest level of customer support, ensuring that TM AI+ AOI Edge is tailored to meet the unique needs of your business. Contact us today to learn more about how our AI cobots can revolutionize your factory’s AOI operations.