Nowadays, while technologies are making our life “smarter”, enterprises and factories are also trying to leverage human powers smarter, by assigning them to perform higher-value tasks such as R&D projects, process planning and etc. So who will handle the daily, basic and repetitive jobs?

Free the Workers from Repetitive Daily Tasks

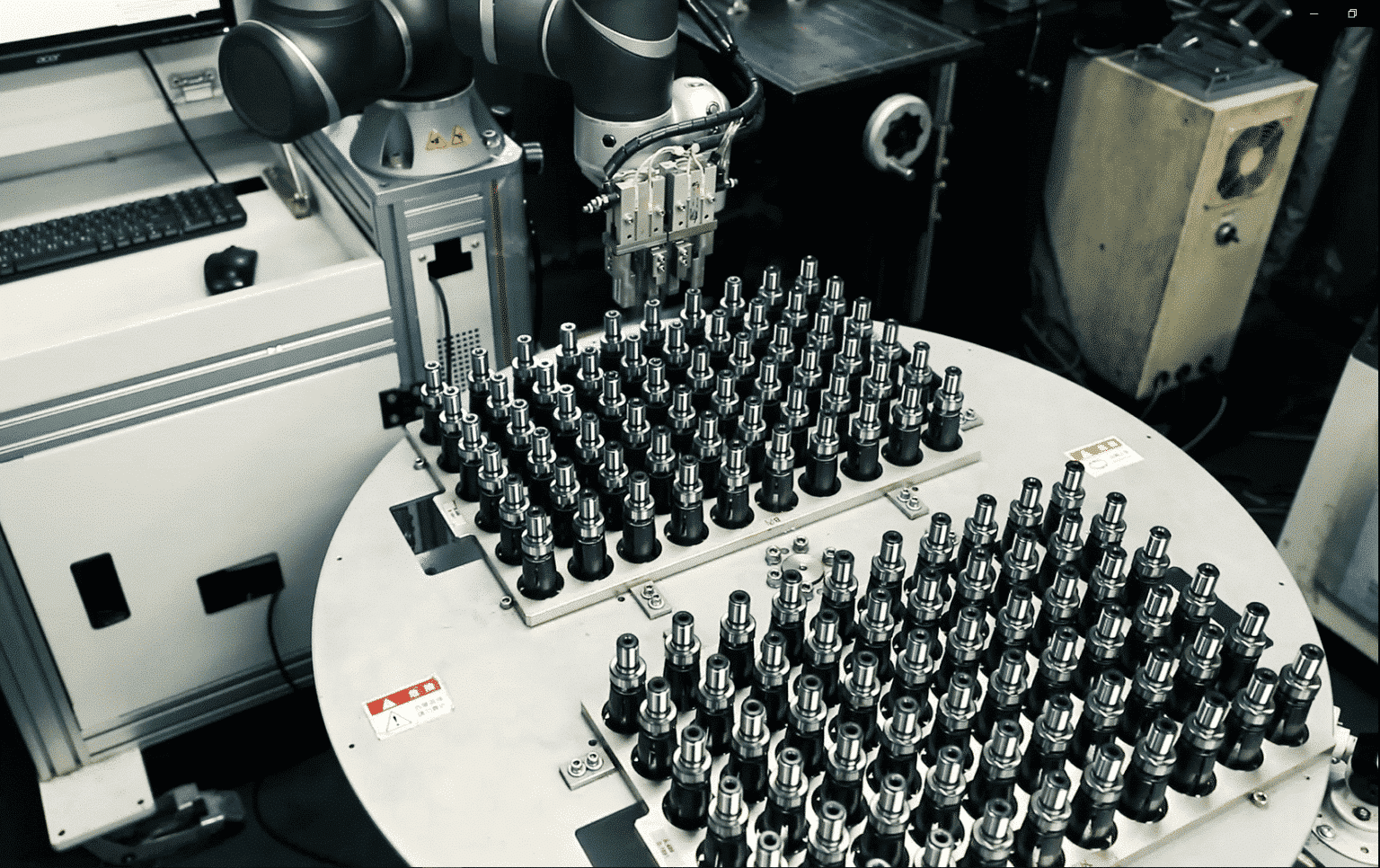

Chumpower Machine Corp., a Taiwanese manufacturer which specialized in providing PET bottle blow molding machines and accessories such as drill chucks, tool holders, and spindles, chose to implement Techman collaborative robots into their production line as a solution to the above question.

System engineer Ping Chen noticed the differences and the improvement in both manpower allocation and working efficiency. “Before we implement TM Robot, our colleague needs to stay near our machines, to complete the process of a certain station. For example, checking on the quality of the goods or transit the goods to another equipment. Now, we make cobots perform all of these tasks. The workers are now free from the stand-by mode and can support other production tasks. This makes a significant improvement, especially when we are having a lot of orders.”

Leveraging the Flexibility of TM Robot

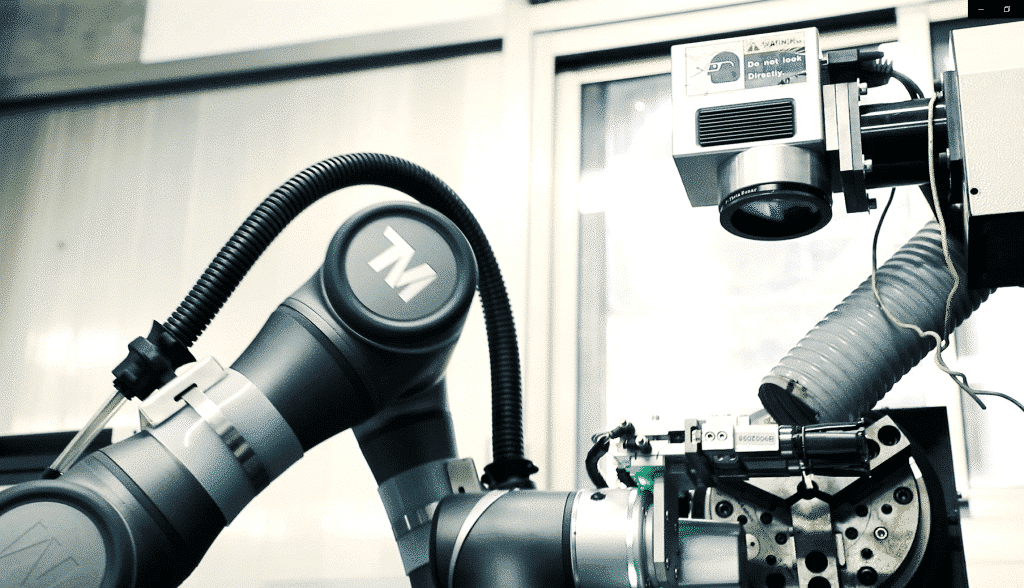

At Chumpower, the engineers are making good use of TM Robot’s flexible characteristics. “We are now implementing TM Robots in our laser graving room and at the end of our blow molding machine. TM Robot is capable of installing customized grippers, so we used a special gripper that can grab 2 workpieces at a time, reducing the cycle time of the process. For the cobot implemented at the end of the blow molding machine, we use the visual function of the robot to determine whether the crystals on the bottom of the bottles have passed the standard and then packed up the qualified bottles in order. More importantly, the HMI of TM Robot is very easy to learn and operate. Users can easily adjust the settings to deal with different types of bottles or production requirements.” Says Ping Chen.

How TM Robots are implemented at Chumpower is a great example that shows cobots are improving the world of work for enterprises. In an era in which human resources are becoming more and more valuable, it’s critical for enterprise managers to allocate their manpower in the most efficient way. TM robots provide these managers more flexibility to do so. And there’s no doubt that with the incredible features and characteristics of TM Robot, these robot arms can cover multiple forms of tasks and applications.