Pick, Place, Perfect: Palletize with Precision & Ease

Robotic palletizing that fits your needs

Have you encountered these problems with an automatic palletizing solution?

Inconsistencies and Sensor Errors

Variations in product sizes and shapes can cause issues, as can errors in the system’s vision sensors and detection capabilities.

Flexibility and Efficiency Challenges

Automatic palletizers may struggle with quick changes in product types or packaging, and may not always meet expected speeds or efficiency levels.

Operational Complexity and Safety

The system could require extensive staff training for operation and troubleshooting, and if safety protocols aren’t strictly followed, there’s a risk of accidents.

Integration and Investment Concerns

Integrating the system with existing warehouse operations can be complex and costly, with significant space and initial financial investment required.

Advantages of using Cobot for Palletizing

Small Footprint

Reduces factory space costs with a compact footprint

Flexible & Versatile

Easily build different pallet patterns by product types to form multiple layers on a pallet

Multi-tasker

Handles a variety of containers simultaneously, such as cases, bottles, batteries, and plastic containers

Fast & Strong

Accommodates payloads up to 30kg tailored to your specific requirements.

Palletizing Development Kit

Enhance safety and profitability with our robotic palletizing wizard, whether it‘s stacking full layers or individual boxes and cases, the wizard provides a fast, reliable, and steady process. Customize your operations using our cobots to design your hardware layout, and easily create and edit tasks tailored to your specific needs.

Choose from a wide range of options including cobot models, software functionality, and advanced AI vision features

•TM AI Cobots from 12~30kg

•Palletizing Wizard

•Force Sensing / Force Control

•AI & 3D Vision

Empowering Your Workflow: Precision in Every Pallet

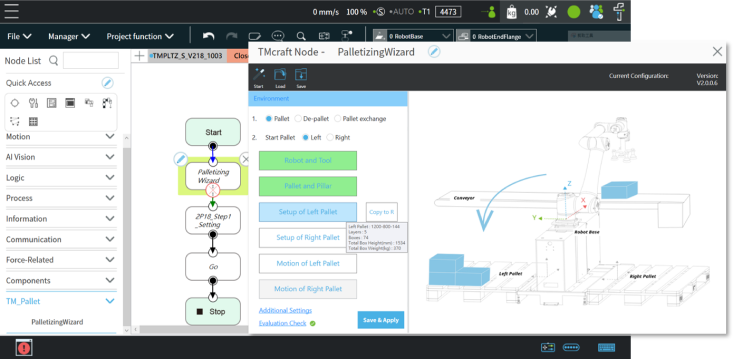

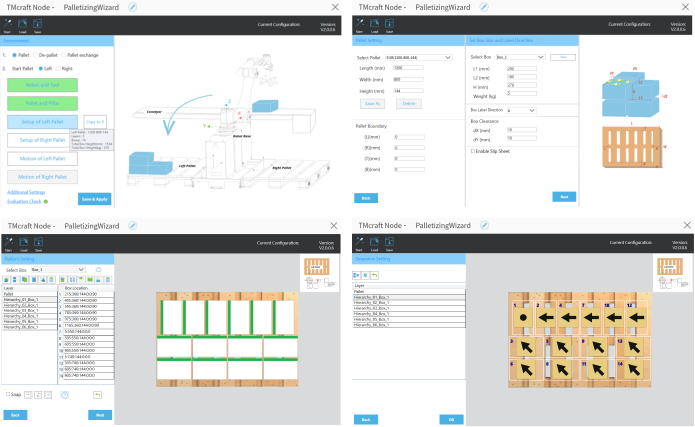

Palletizing Wizard

Developed by TMcraft, the Palletizing Wizard offers a versatile range of functions including palletizing, depalletizing, and pallet exchange. It seamlessly integrates with TMflow, allowing for customizable box and pallet sizes, along with flexible arrangements of box patterns and sequences.

Advanced Operating Features

Enhances efficiency by generating point files directly in TMflow. It also features sophisticated palletizing simulations and collision detection capabilities, ensuring precision and safety in operation.

User-Friendly Interface

Intuitive flow programming, features a ready-to-use user interface for streamlined robotic palletizing designs, centralizing most operations into a single interface, ensuring ease of use for all skill levels.

Effortless Mixed Depalletizing

The integration of a 3D camera in our development kit allows you to have mixed cases depalletizing application in your field. The built-in AI model supports a wide variety of target objects, creating a seamless depalletizing process for items of different sizes and shapes.

Universal Compatibility

Supports standard camera connections, allowing it to receive 3D images from a wide array of 3D cameras on the market.

No Platform? TM Palletizing Operator is for you!

TM Palletizing Operator is an all-in-one solution designed for palletizing automation that simplifies setup with built-in software, offering quick specification adjustments, simulations, and collision tests. It reduces pallet setup time from months to minutes, suitable for industries like warehousing, logistics, food processing, and manufacturing.

Elevate Efficiency: Revolutionizing Palletizing from Setup to Operation

- 17 certified PL=d cell level safety functions

- Palletizing speeds reach up to 7 boxes/min for TM12, and 5 boxes/min for TM20

- Adjustable pillar with a 1200mm reach and 2325mm maximum stacking height, with three pillar stroke options available

- IP54-rated cobot, IP65-rated teach pendant, and IP32-rated end-effectors and accessories

- Compliant with multiple safety and quality certifications, such as CE Machine Directive 2006/42/EC, ISO 12100, EN-60204-1, ISO 10218-2, ISO 13849-1, ISO/TS 15066