Techman Robot has announced a strategic collaboration with Panasonic Connect’s Welding Systems Division, aiming to accelerate the development of welding automation solutions.

By combining Techman Robot’s advanced collaborative robot technology with Panasonic’s extensive experience in the welding field, the two companies are opening new opportunities in the automation of welding processes. Since establishing their partnership in 2023, both parties have been working closely to meet market demands and will now strengthen their activities in the Japanese market.

To simplify robot welding setup, Techman Robot has developed the “Welding Node” module. This new solution integrates seamlessly with Panasonic’s fully digital welding machines, helping to address the growing labor shortage in the welding industry by streamlining automation.

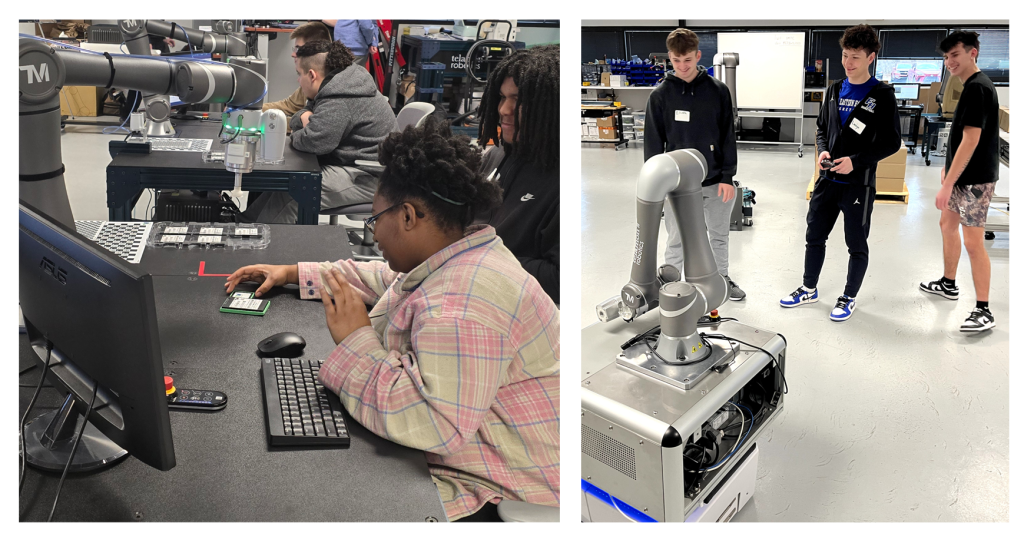

Techman Robot’s built-in vision system and AI functionality also contribute to intuitive, simple, and flexible operation. These features are expected to further enhance automation on welding lines.

By combining their technologies, Techman Robot and Panasonic aim not only to accelerate automation but also to expand applications through evolving AI capabilities.