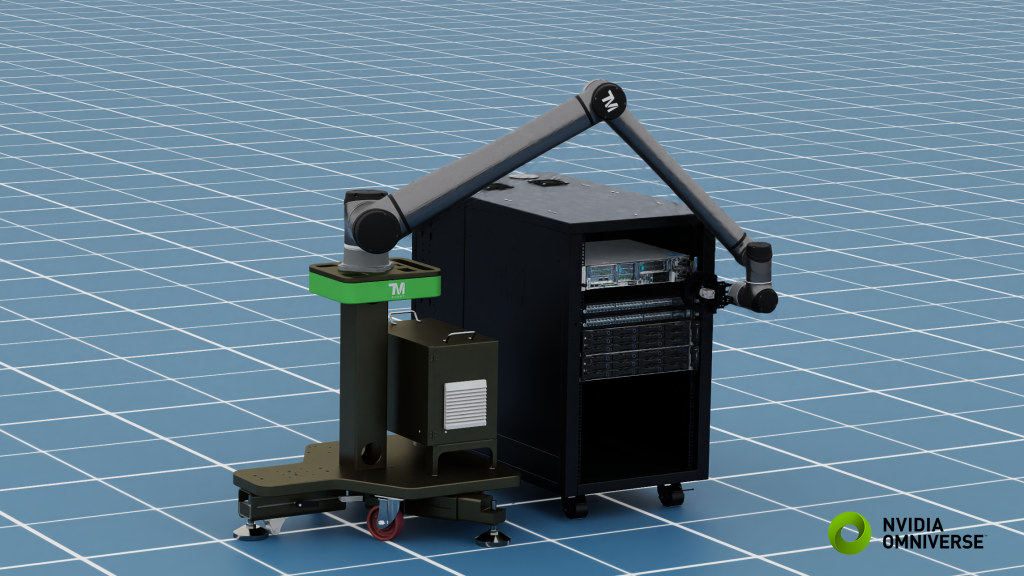

As smart manufacturing evolves, the integration of digital twins and AI is accelerating—bringing greater flexibility and automation efficiency to the factory floor. At COMPUTEX 2025, Techman Robot, in collaboration with QCT and NVIDIA, is showcasing an AI-driven inspection solution that combines collaborative robots with digital twin simulation, demonstrating a complete journey from planning and deployment to optimization in future-ready smart factories.

Zero-Touch Deployment: High-Efficiency Integration with Omniverse Digital Twins + Flying Trigger Technology

Before deploying automation equipment, manufacturers often face key concerns: Are inspection points precise enough? Is there enough space for robotic arms to move? Will the cycle time meet expectations?

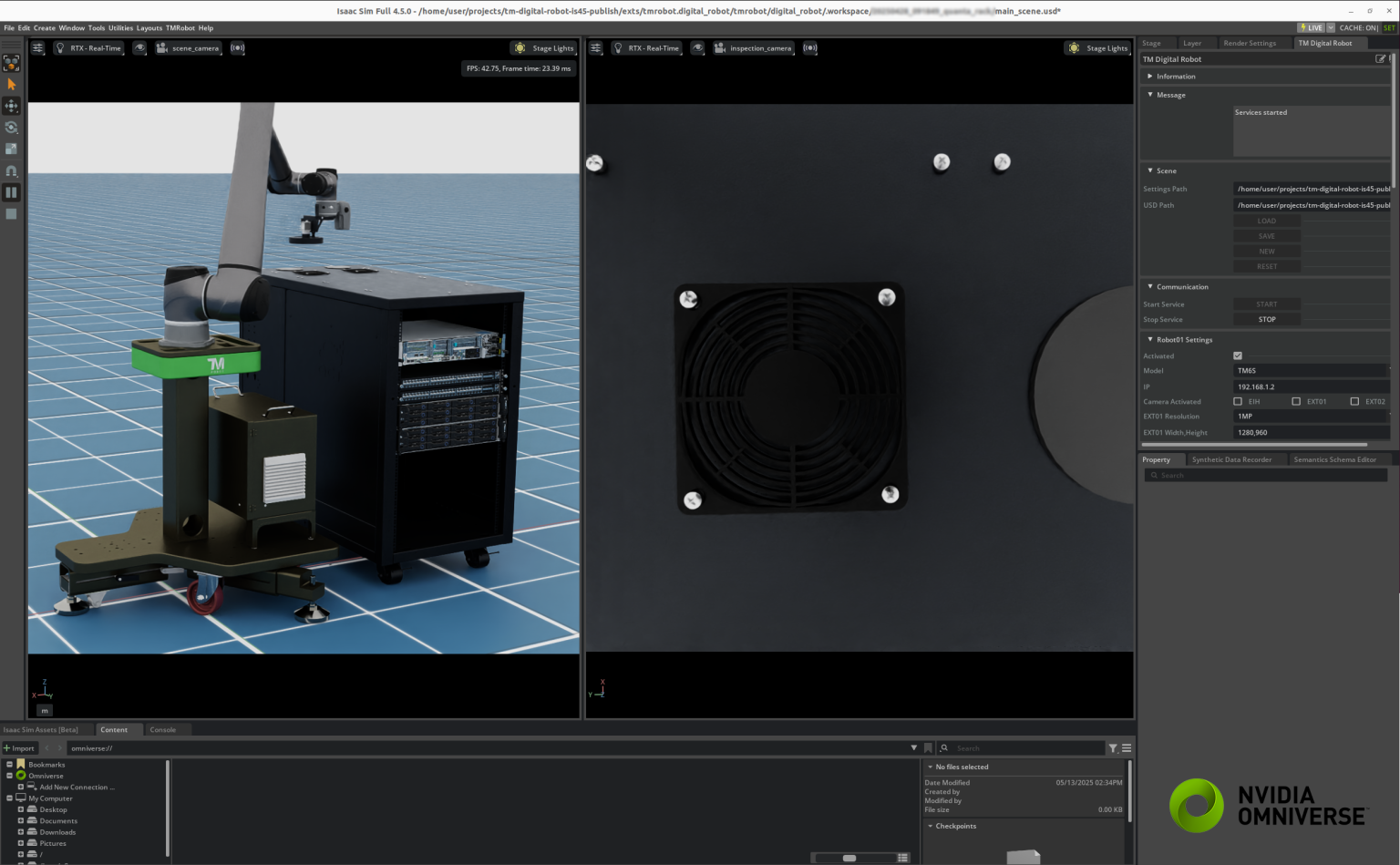

To address these challenges, Techman Robot utilizes NVIDIA Omniverse libraries to develop high-fidelity digital twin factory environments that simulate motion paths, vision detection points, and task timing. This enables the engineering team to validate the entire workflow before deployment, significantly reducing trial-and-error on-site and avoiding unnecessary downtime—achieving true zero-touch integration.

This demonstration also features Techman Robot’s proprietary Flying Trigger inspection technology, which combines AI algorithms with high-speed imaging to detect defects in real time—even while work pieces are in motion. The system enables zero-downtime quality inspection and has been shown in real deployments to reduce inspection time by 40–50%, greatly improving cycle time and overall production efficiency.

Proven effective in server manufacturing and other high-precision industries, this solution minimizes human error and labor costs, delivering a fast, stable, and scalable inspection system. The synergy of Omniverse robot simulation with Flying Trigger technology reflects Techman Robot’s deep integration capabilities and leading-edge expertise in smart factory planning and deployment.

Data-Driven Intelligence: Accelerating AI Model Readiness with Omniverse Synthetic Data

Traditional AI vision models rely heavily on real-world image data, often facing bottlenecks in cost, diversity, and acquisition speed. Techman Robot addresses this by training AI models using synthetic images and virtual defect scenarios generated with Omniverse technologies—significantly shortening development time.

By simulating scenarios like cable misalignment, incorrect LED indicators, fan displacement, or faulty tray insertion, engineers can build robust vision models without depending on time-consuming physical sample collection. These models are deployment-ready from the outset, delivering high stability and accuracy even in the early stages.

This synthetic data pipeline not only reduces development costs but also highlights Techman Robot’s innovation and adaptability in industrial AI applications.

A New Standard: AI × Digital Twin is Reshaping the Factory Floor

From digital twin simulation and virtual data training to edge deployment, the solution developed by Techman Robot with NVIDIA and QCT is more than just a proof of concept—it’s a blueprint for scalable, production-ready smart manufacturing.

Through real-world validation, we demonstrate how the AI Cobot—developed with Omniverse—can deliver efficient, stable, and intelligent autonomous inspection across dynamic environments.

Looking ahead, Techman Robot remains committed to driving the next phase of industrial transformation, with AI collaborative robots at the core, enabling factories to move beyond automation and toward a future defined by greater agility, predictive power, and data-driven decision-making.