Across the world, the COVID-19 pandemic has disrupted the global supply chain and exposed the limited resilience of many manufacturers. Some manufacturers have ceased production completely, many have seen a great reduction in demand, and others have experienced a huge surge in demand. With a global recession looming, those who have fragile supply chains, insufficient agility, and overdependence on human assets will be left behind. The need for manufacturing industries to step up performance and invest in smart factory production, otherwise known as Industry 4.0, has never been greater.

Industry 4.0: Then vs Now

Prior to the pandemic, industry 4.0 was only an area of interest and an exciting subject brimming with potential benefits to many manufacturers. It was only seen as a positive and future thinking topic. Business-drivers of industry 4.0 pre-COVID focused on cost reduction, competitive advantage, productivity, innovation, and sustainability. The goal was to make businesses with well-oiled operations run better.

Today, however, the focus for many manufacturers is survival, damage limitation, recovery, and business as usual in the next normal. To achieve all of these, they will have to leverage the benefits that industry 4.0 and smart factory offer in the aftermath of COVID-19.

The Future is Now: How Industry 4.0 is Reshaping Manufacturing in the Time of COVID-19

In the next few years, or even months, the manufacturing sector is set to become more digitalized, with the adoption of smart factory and other advancements further sped up by the effects of the pandemic. After all, some key manufacturing hubs in Asia such as China, Japan, and South Korea have maintained consistent production despite limited manpower availability due to their use of the Industrial Internet of Things (IIoT) and sensors to monitor production. With social distancing becoming more prominent in factories, there’s also the pressing need to invest in automation equipment that improves efficiency and reduces emergency interruptions and downtime.

The role of Industry 4.0 in the current pandemic and the next normal include:

- Helping companies survive the crisis

- Shorten the recovery phase so businesses can return to normal operations as soon as possible

- Provide the platform to develop improved resiliency among businesses

Industry 4.0 can easily achieve this role due to the many capabilities it offers to the manufacturing sector. A few examples are:

- The Internet of Things – more devices connected to a central controller, allowing manufacturers to gather more data as well as efficiently streamline and digitize their processes

- Big Data – data comes in from various sources enabling manufacturers to make well-informed, real-time decisions

- Machine to Machine Communication – real-time visibility into the availability of raw materials, works in progress, finished goods, and other assets

- Safety – assistance with skills shortages due to social distancing and self-isolation. Technologies enable more virtual working and remote setups to help with the issue of lockdowns and quarantine protocols.

Companies that have not invested in smart factory advancements are likely to discover that doing so will spur and hasten their comebacks after the COVID-19 pandemic. Manufacturers will see that dependence on high-tech innovation will make operations stronger and more efficient within weeks or months, as well as in the long stretch.

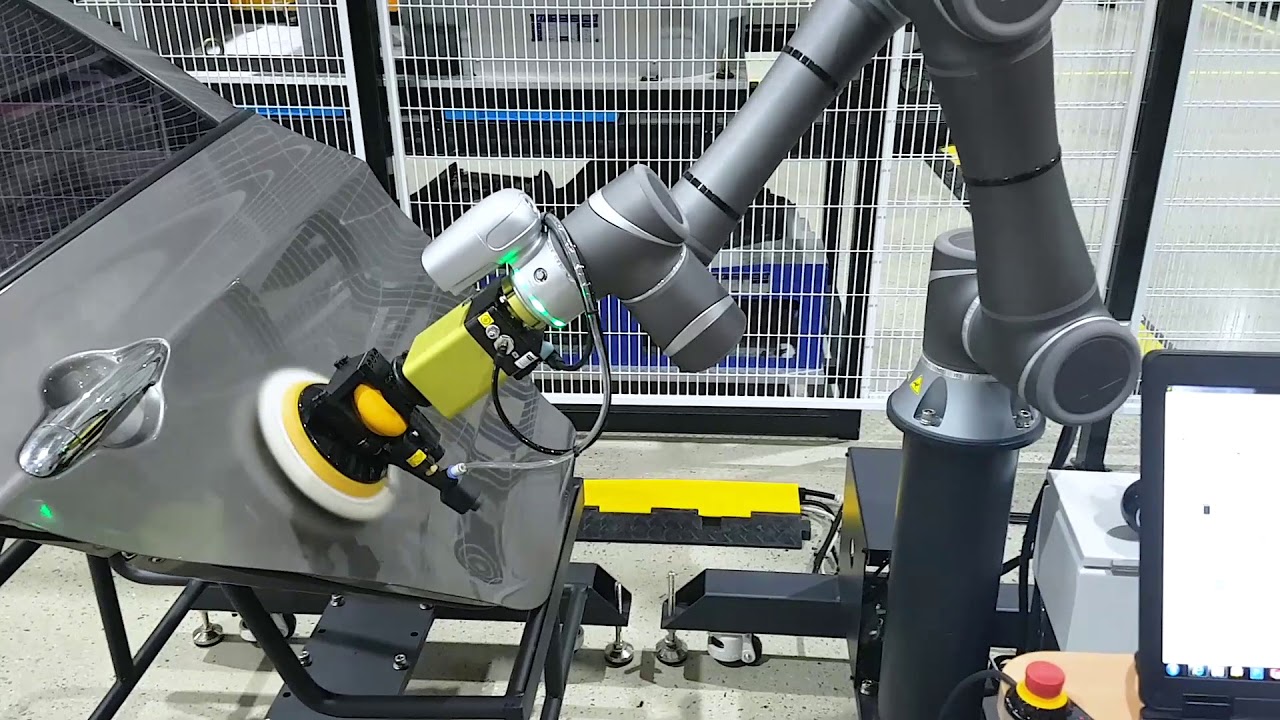

For more information and inquiries about industry 4.0 and automation solutions for your factory, don’t hesitate to contact Techman Robot today. We’re a leading collaborative robot and vision technologies company with a wide range of smart factory solutions to improve businesses and their people through innovative robotic technology applications.